U.S. power management product manufacturer, ASCO Power Technologies, has reduced programming time by 75% and increased efficiency with new nesting...

Learn More

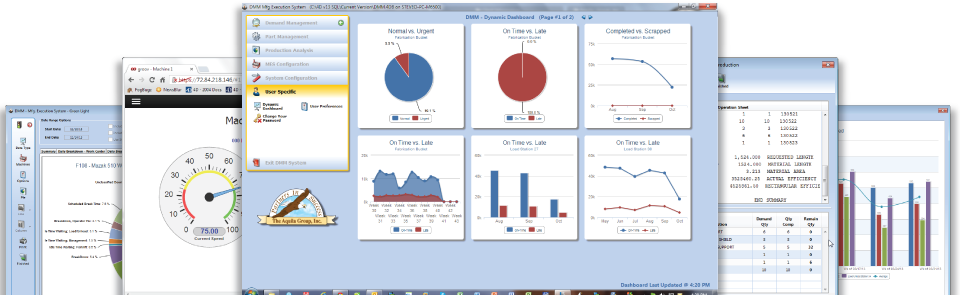

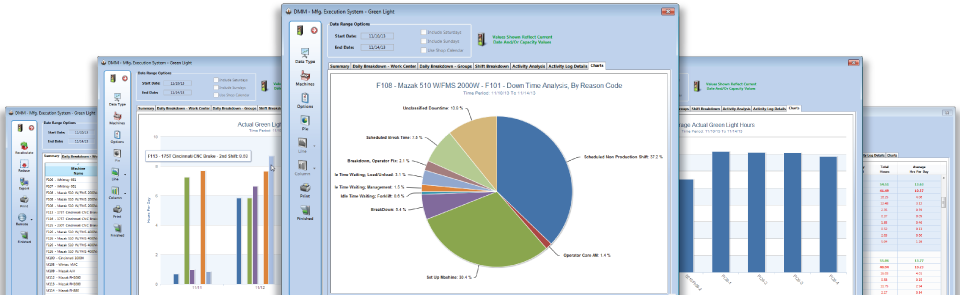

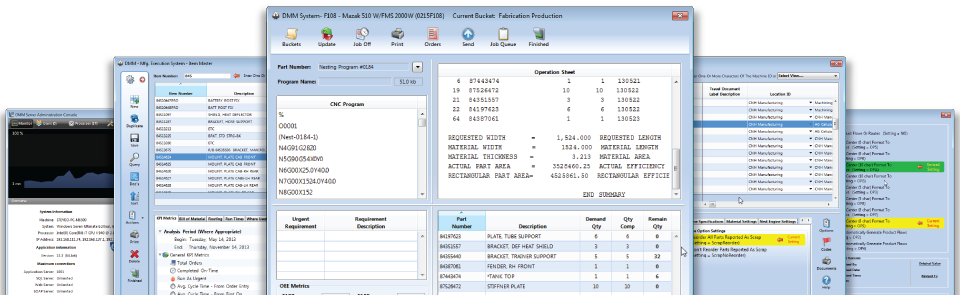

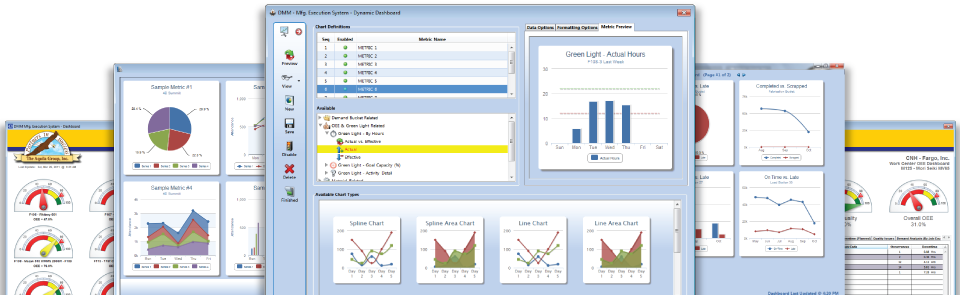

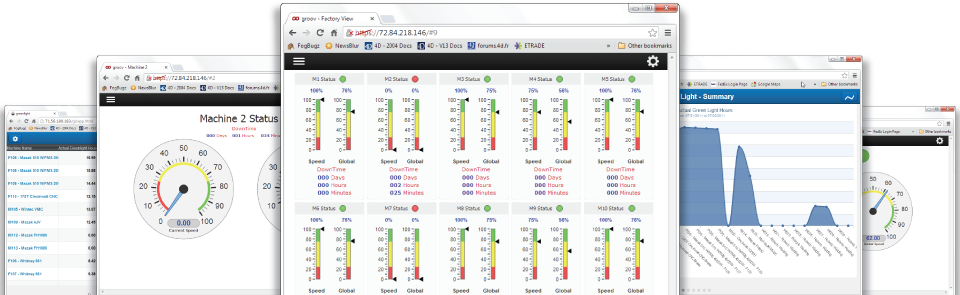

To help its manufacturing customers integrate OEE measurements with Enterprise systems, The Aquila Group has implemented data visibility systems with Opto 22 platforms. Read all about it in Automation News...

Learn More

Implementing manufacturing execution systems (MES) or enterprise resource planning (ERP) systems that also integrate overall equipment effectiveness (OEE) monitoring can be a daunting task. The Aquila Group, Inc. is tackling this problem directly. Using the technology powering the Industrial Internet of Things (IIoT), they have begun knocking down those barriers, providing a bridge between IT and OT resources. Their customers, from smaller manufacturers to large ones like Eaton Electrical, Kohler, Fiat, and Siemens, now have visible data for process improvement, without disrupting current...

Learn More

Long time customer, Hillphoenix Inc. recently integrated the JETCAM nesting solution on multiple Amada punch and laser work centers, along with a Salvagnini laser work center. Read all about the impressive results achieved in the case study: Also please visit our partner on this project, NestONE Solutions, for more information on how they can assist you achieve similar...

Learn More